PUNCHING TECHNOLOGY

Proven VEITH quality for your field of application

"From a punch supplier of the first hour to a system supplier" - this is how VEITH's development in the field of punching technology can be briefly described. Over the decades, we have set standards with our quality standard, which are still optimized today, because quality and precision are our passion. We offer a wide range of products for the multitude of possible applications.

PUNCHING TECHNOLOGY

- Tool life increase due to ground surface

- Coordinated heat treatment

- Application optimized products

We offer a wide range of punch designs in various materials for the multitude of possible applications. Heat treatment tailored to the material and application, as well as any form of surface treatment are part of our range of services.

PRODUCT RANGE

With toolmaking standards from Veith, you are always on the safe side. For the growing demands of the market in the field of toolmaking, Veith always provides you with the right solution. The experience from our in-house tool shop as well as our stamping shop offers us unique possibilities to provide optimal advice and individual service.

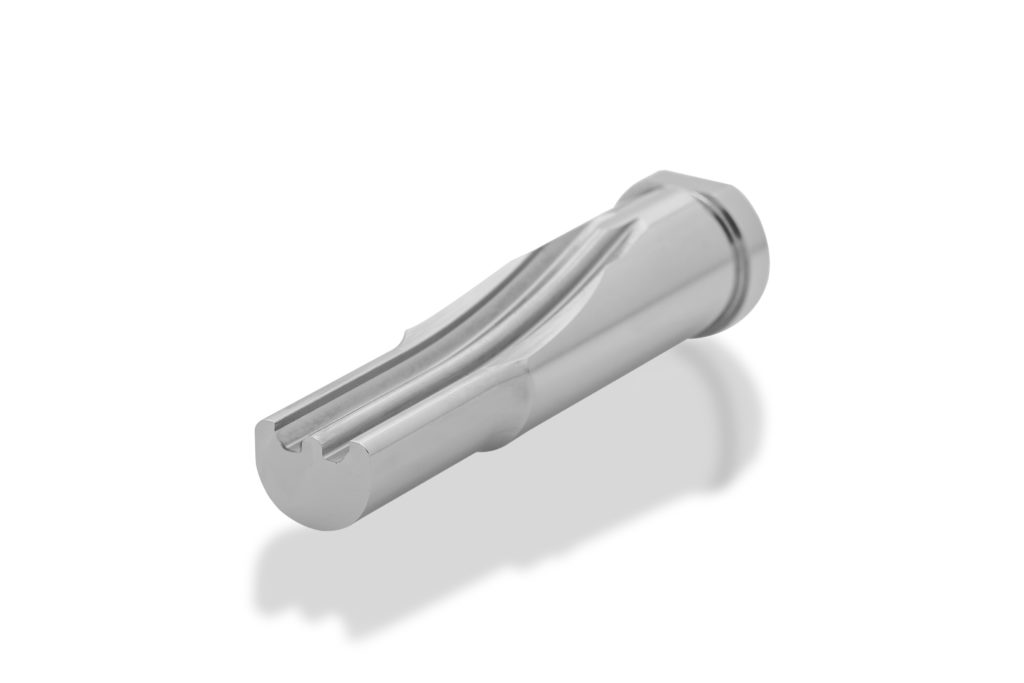

We are your problem solver when it comes to borderline applications. With our own developments, such as the trombone neck punch, but also with a good network in the areas of raw materials and surface technology, we can offer the optimal product for your application. Increase your productivity, reduce your downtimes, increase the service life of your tools - all this is our incentive and our core competence.

Cutting stamp

- Coordinated heat treatment

- DIN stamp or special design

- 24 hours delivery service

- Product supplement: journal counterbore

- Standard stamp according to DIN/ISO

- Drawing special postmarks

- Tool life increase due to ground surface

Cutting and guiding bushes

- CERVICAL SPINE

- HSS

- Powder metallurgically produced steel

- Carbide

- Delivery incl. waste protection

Guide elements

- Smooth according to ISO 9182-2/ DIN 9825

- For large tool making ISO 9182-3/DIN 9833

- With collar ISO 9182-5/ DIN 9833

- With center waistband

- Interchangeable guide column with conical shaft ISO 9182-4/ DIN 9825

- With collar ISO 9448-6/ DIN 9831

- With flange 9448-4/ DIN 9831

- Steel/bronze with solid lubricant 9448-2/ DIN 9831

- Ball bearing bushes smooth and with collar ISO 9448-7/ DIN 9831

- Ball cages

- With bronze collar with solid lubricant ISO 9448/ DIN 9834

- Roller guides

Marking tools

- CERVICAL SPINE

- HWS Premium

- ø-38 and ø-40 available

- With or without embossing die for layer display

- round and oval design

- incl. 2 engraving fields (part number & multiple part number)

- alternatively with three engraving fields for additional factory marking

Punching oil

- High performance machining oil

- Very low fog

- high rinsing and cooling effect

- clean surfaces free of scoring

- Optimum tool life

- High separation effect between the friction partners workpiece and tool

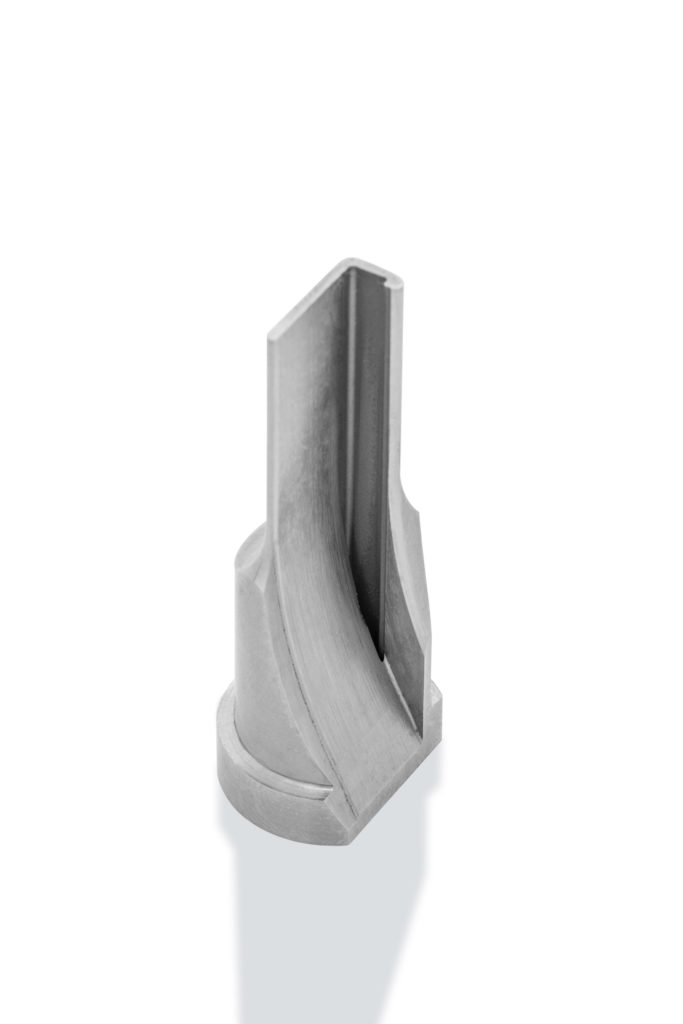

Tenon counterbore

- Tenon counterbore for trombone neck

- Countersink for 60° - countersunk head according to DIN 9861

- Set also available in wooden storage boxes